How marine chronometers shaped horology today

Fergus NashNavigation is definitely taken for granted these days. Not that I don’t personally rely on Google Maps to take me pretty much everywhere, but the art of traversing the globe was one of the most difficult, frightening, and often heroic skills for thousands of years in human history. As if finding your way through icy mountains or endless deserts wasn’t tough enough, try to imagine sailing in the right direction while there’s no stable land in sight, wind and currents conspiring against you. That was the task of nautical navigators, and the birth of the marine chronometer was the first major step towards the digital tools we have today, as well as our modern wristwatch accuracy.

As with any form of navigation, the first step to finding out where you’re going is to find out where you are. Determining exact position on Earth requires latitude, longitude, and altitude, although altitude can pretty much be ignored when you’re travelling exclusively at sea level. Latitude (North-South) is relatively easy to determine by measuring the sun’s angle at midday or the North Star at night, but the longitude (East-West) is much more difficult. A method was devised in the 1553 for estimating longitude with a clock by the famed Dutch mathematician Gemma Frisius, but it was far too early to be practical. The most accurate clocks at the time were pendulum-based, and that’s not a technology which thrives on open ocean. However, the cogs were certainly turning in the age’s most brilliant minds to find an accurate and safe alternative.

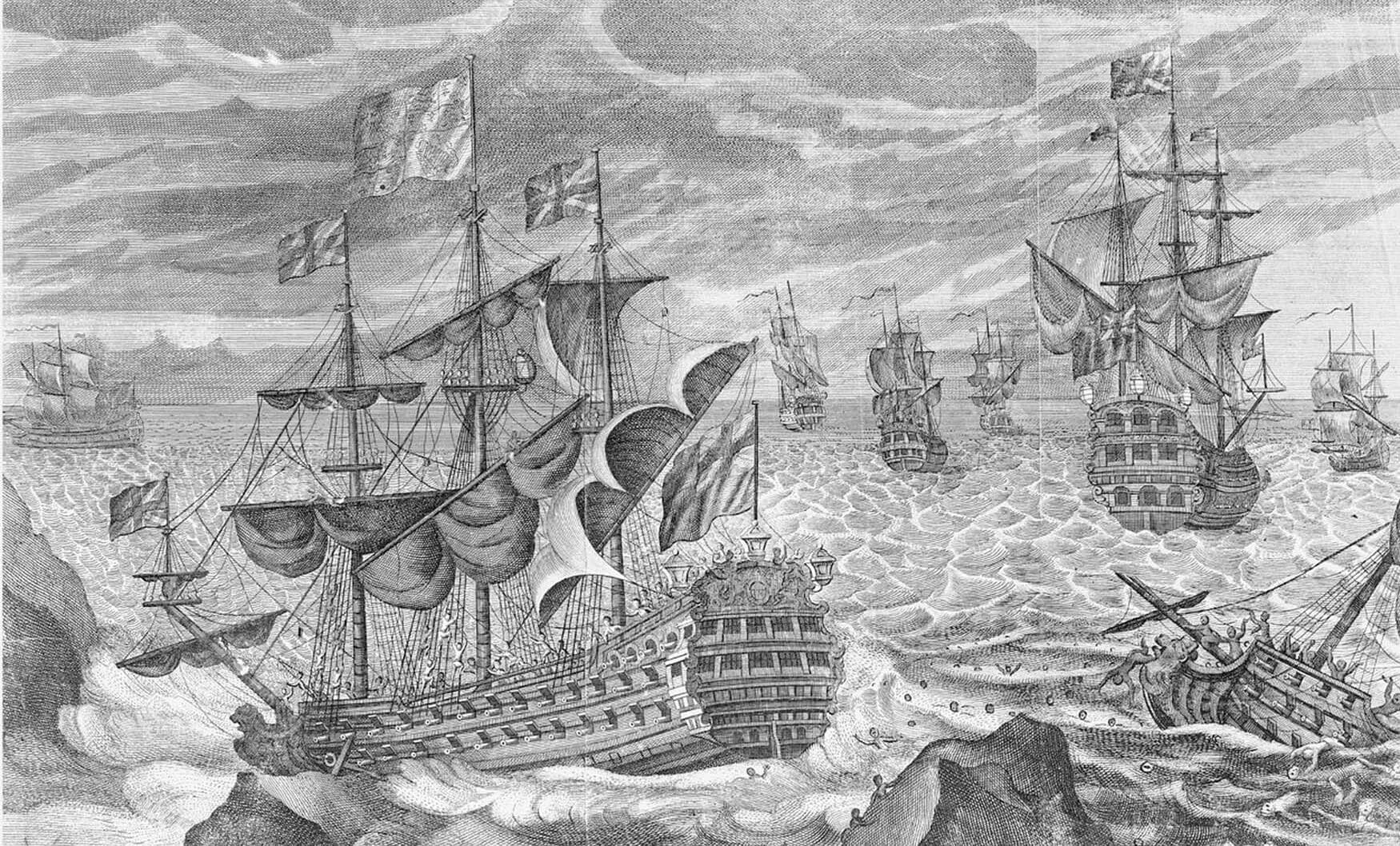

The earliest-known use of the word ‘chronometer’ was published in William Derham’s book Physico-Theology from 1713, as it touches on possible avenues of making more accurate timepieces. After nearly 200 years of theorising and offshoot technological advancements, the British were finally set to put the clock on the matter. The Longitude Act of 1714 established the Board of Longitude, essentially offering cash incentives to anyone who could produce a working marine chronometer. Similar prizes had been offered throughout history, even as early as 1598 by Philip II of Spain, but none that produced reliable results. After four Royal Navy warships had been lost due to navigation errors in the Scilly naval disaster of 1707, Britain was desperate for a solution.

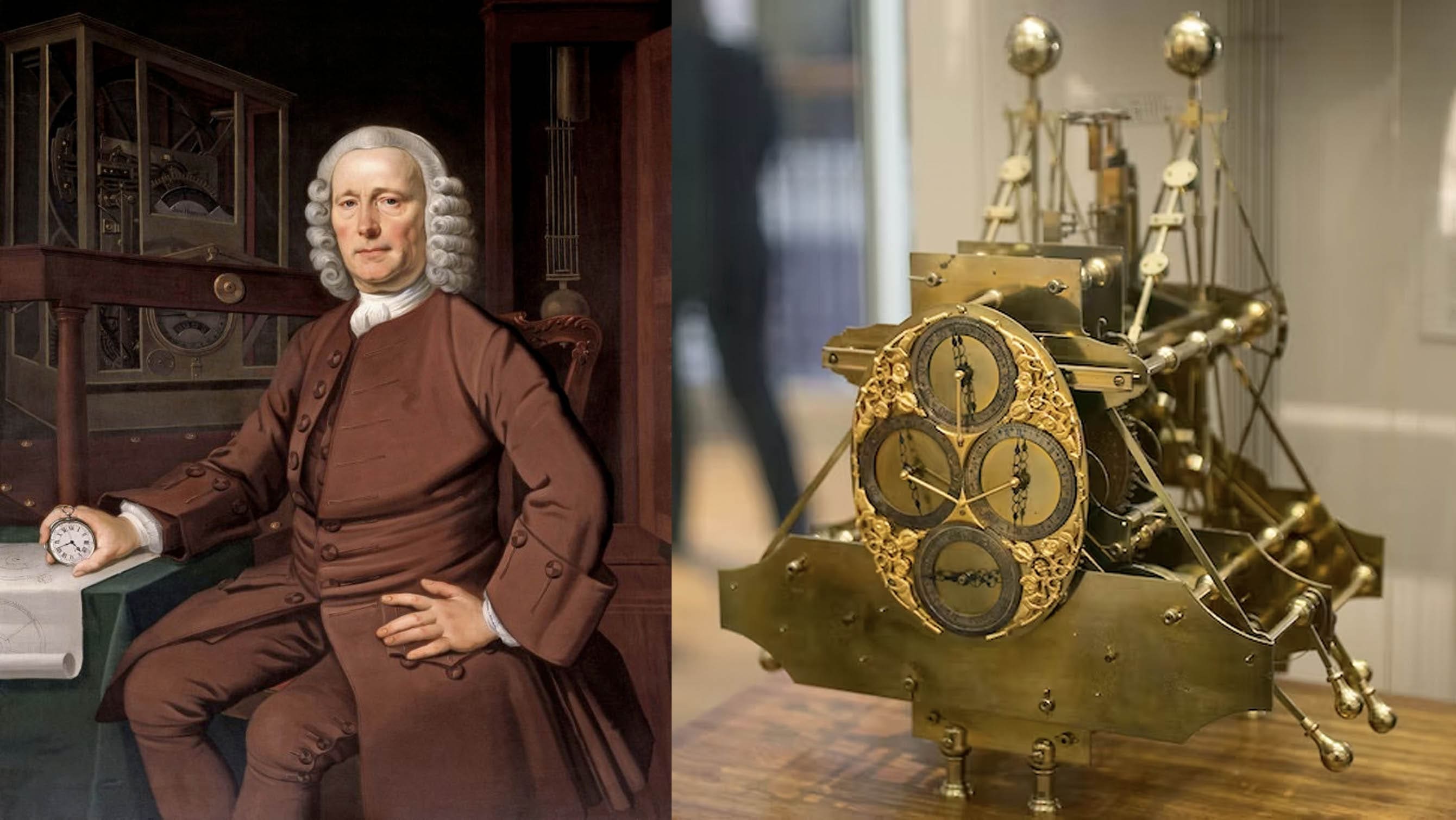

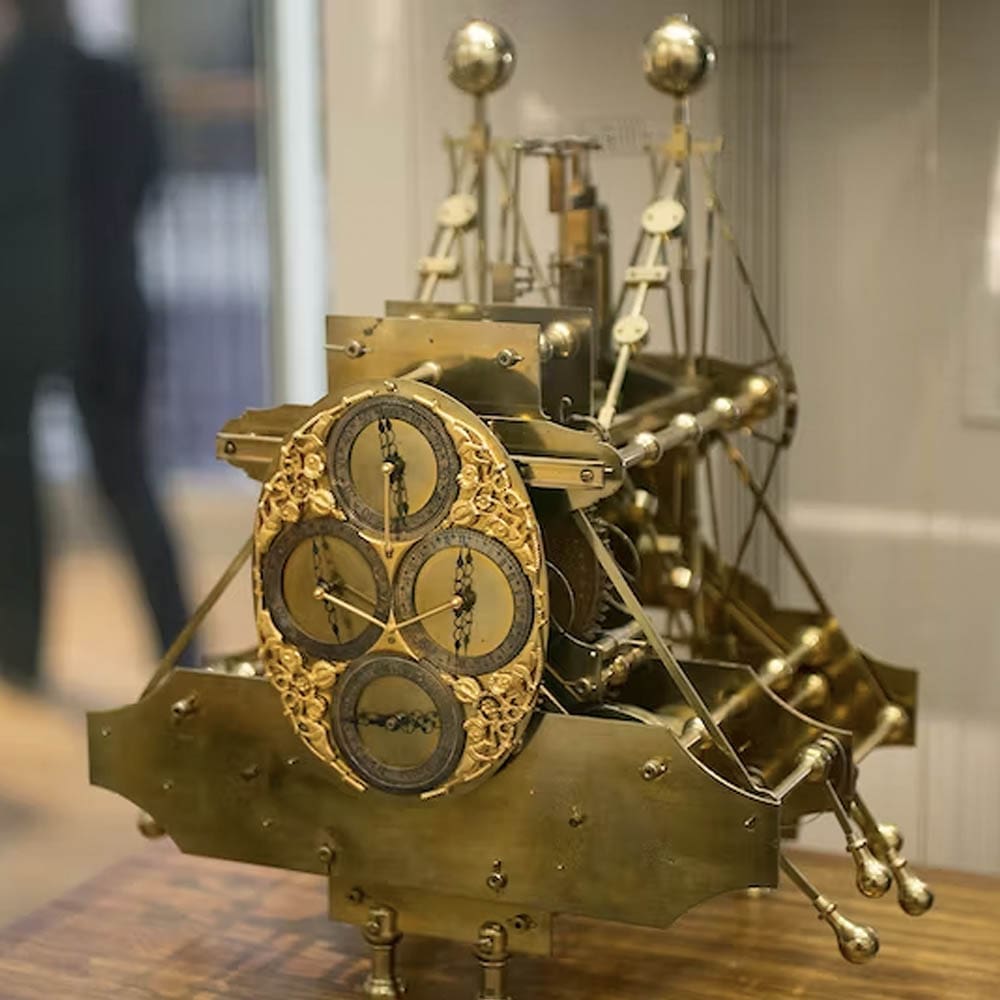

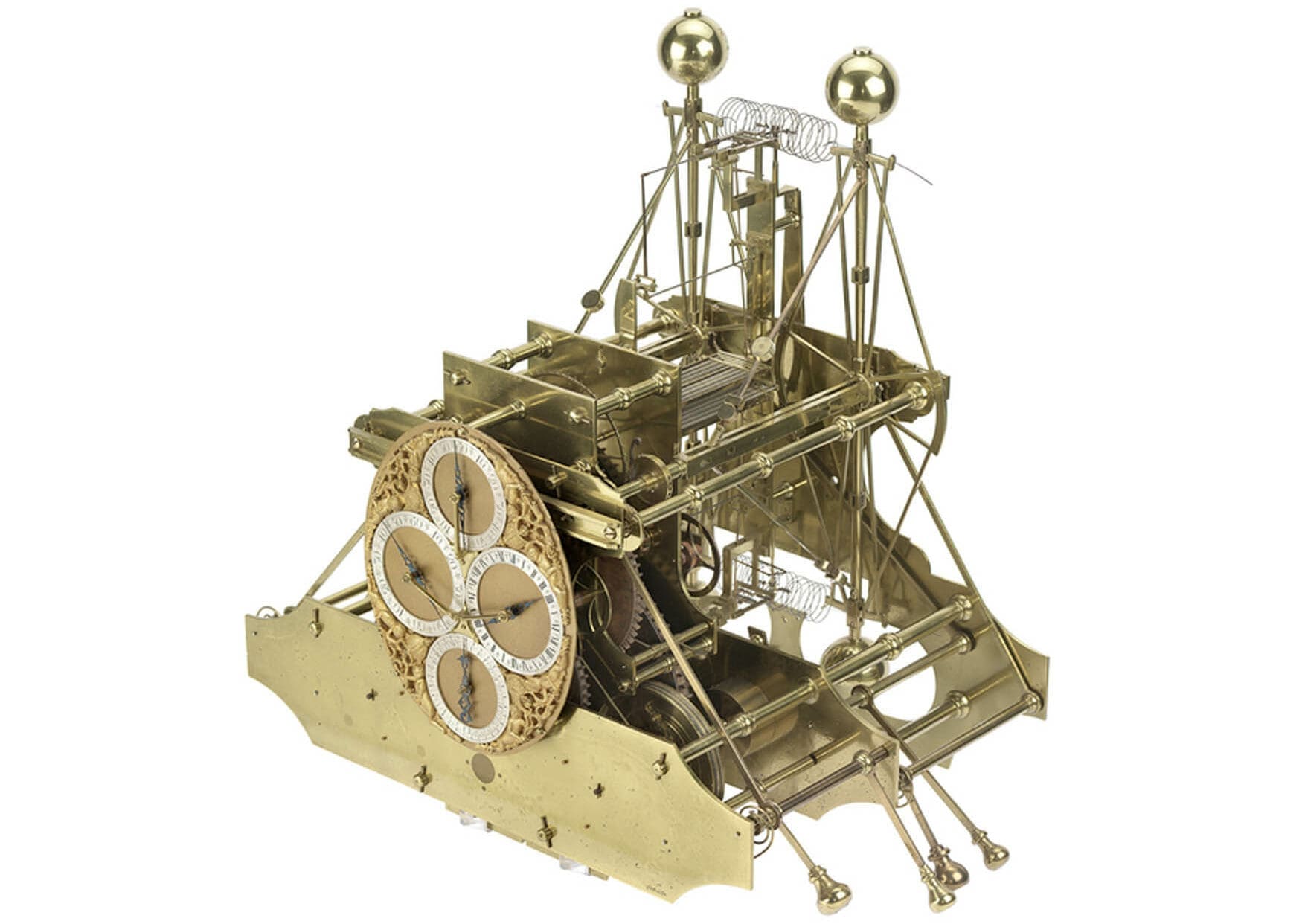

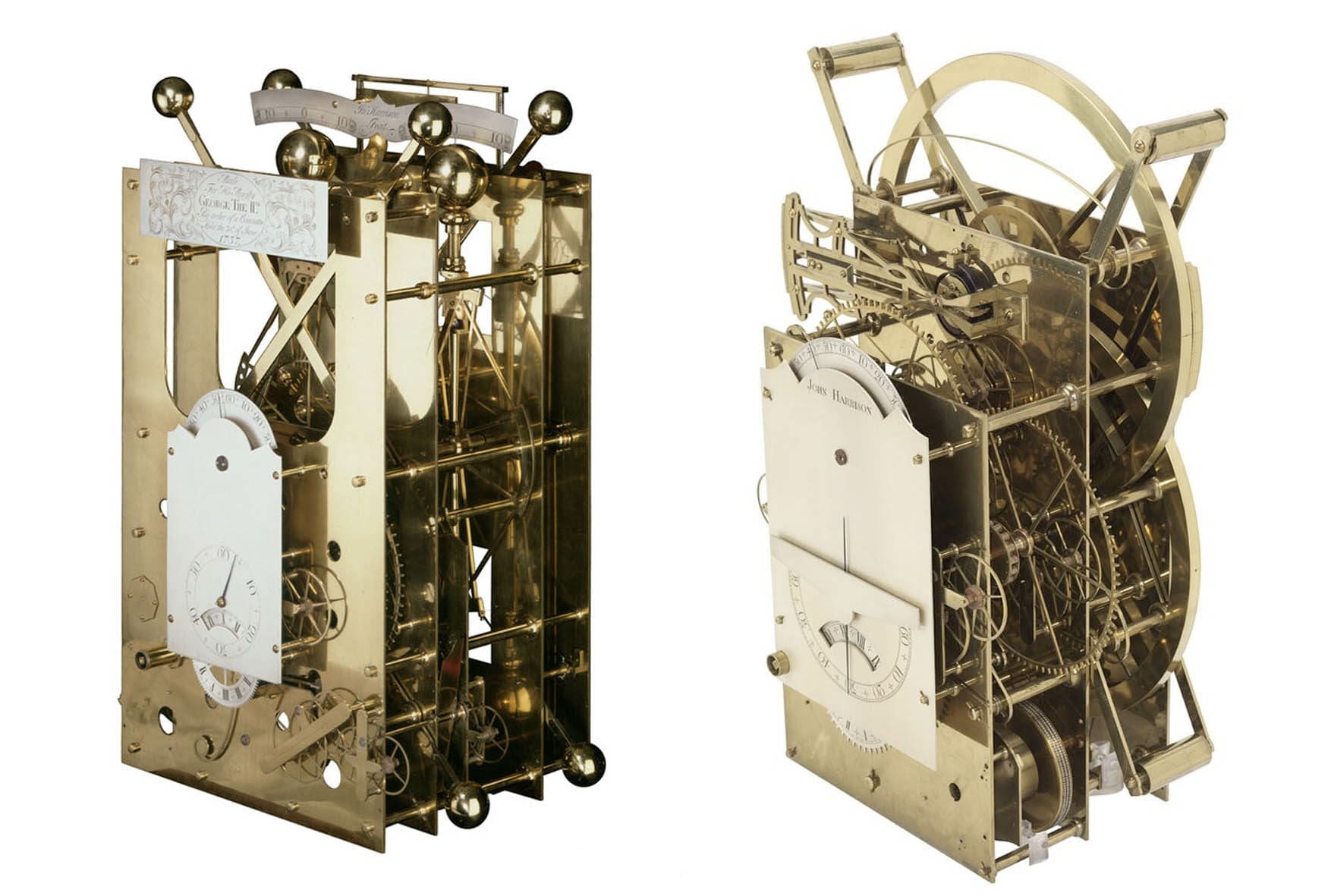

There were many recipients of longitude rewards, but by far the most successful was John Harrison. His total prize pool was £23,065, worth over £3 million today, split across 36 years of dedicated work. After a loan from the famous George Graham, Harrison spent five years building his first sea clock. Being the first example deemed sea-worthy by the Board of Longitude, the chronometer known as the ‘H1’ sailed to Lisbon and back in 1736. It did lose a bit of time on the way there, but the return journey was an exciting success. Compared to the longitude calculations of the ship’s master, Harrison’s H1 led to a correct position while the master was 60 miles off. Testing of the H2 was cancelled because of Britain’s war with Spain, but Harrison realised that the design was flawed regardless. This flaw led to his adoption of circular balance wheels, replacing the foliot which used a pivoting bar with weights attached. The H3 design was also unsuccessful, but along the way he pioneered the bimetallic strip that compensated for thermal expansion and the caged roller bearing which reduced friction.

While the quest for a foolproof marine chronometer was proving to be fraught with physics issues that the engineers of the time couldn’t yet understand, pocket watches were racing ahead. Harrison’s first three sea clocks were huge and bewitching contraptions, standing over 60cm tall, and far from the convenience of a watch. Thomas Mudge, a student of George Graham and the inventor of the lever escapement, had been making watches that were just as accurate as Harrison’s clocks. Realising that smaller-scale watches were capable of chronometer status, he switched gears. Aided by some of London’s best watchmakers, Harrison designed and created the H4 in 1759.

It would take a book to fully investigate all the innovative techniques of the H4, but among them were diamond pallets in the escapement, a balance-break which stopped the watch from being fully wound down, and temperature compensation. It took six years to build, and initial testing revealed an accuracy of -2.66 seconds per day. This was seen as a huge success from everyone involved, however, the following years would be strenuous. The Board of Longitude’s testing also showed good results, however they refused to pay out the grand prize for various reasons, including the time it had taken to make the watch, and chalking the results up to luck. While the H4 was essentially held hostage by the Board for their own ‘tests’, Harrison began work on the H5.

After feeling “extremely ill-used by the gentlemen who I might have expected better treatment from”, John Harrison decided to go over the Board’s head and met with King George III. The King was upset with the Board for ultimately impeding progress of this life-saving technology, and took to conducting his own tests on the H5. After daily observations over 10 weeks in 1772, the H5 was found to be accurate within 0.33 seconds per day. After the threat of a stern dressing-down from King George III, the Board of Longitude finally recognised Harrison’s achievement officially and handed him £8,750, still just a fraction of the £20,000 that had been promised. The H4 went on to be cloned for the likes of James Cook, who continually praised its excellent accuracies.

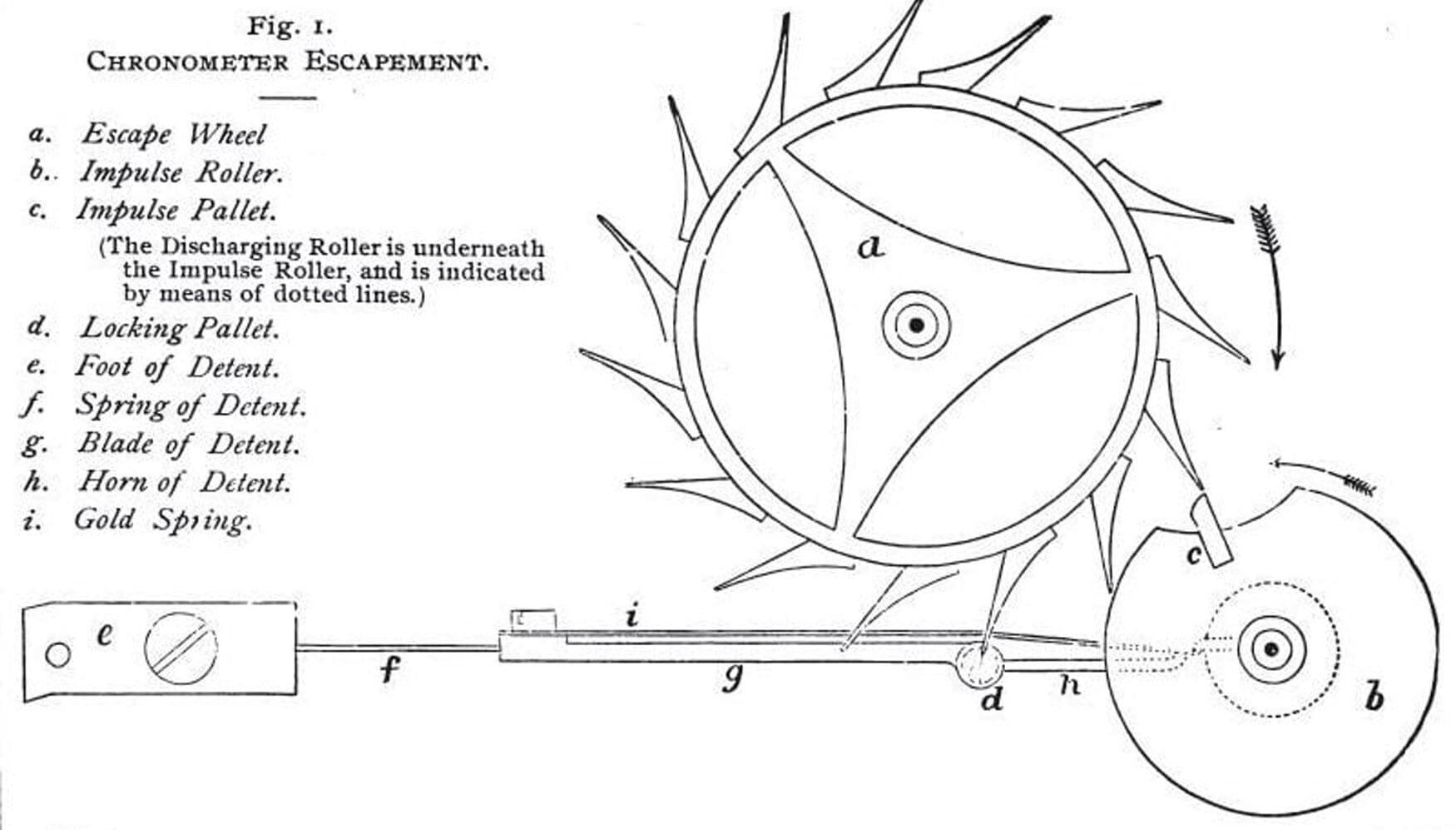

John Harrison did receive credit and some prize money for his achievements, but development didn’t stop there. Notable names in the pursuit of marine chronometry after Harrison include Ferdinand Berthoud, Thomas Mudge, Thomas Earnshaw and John Arnold, all proving that Harrison’s design wasn’t the only one which could show results. The latter two in particular revolutionised escapements, relocating temperature compensation to the balance and improving the overall manufacturing process for balance springs. This would later become a standard design for all chronometers, which also found its way into wristwatches eventually. Their timepieces were capable of keeping time within one second per day, outperforming the legendary H4.

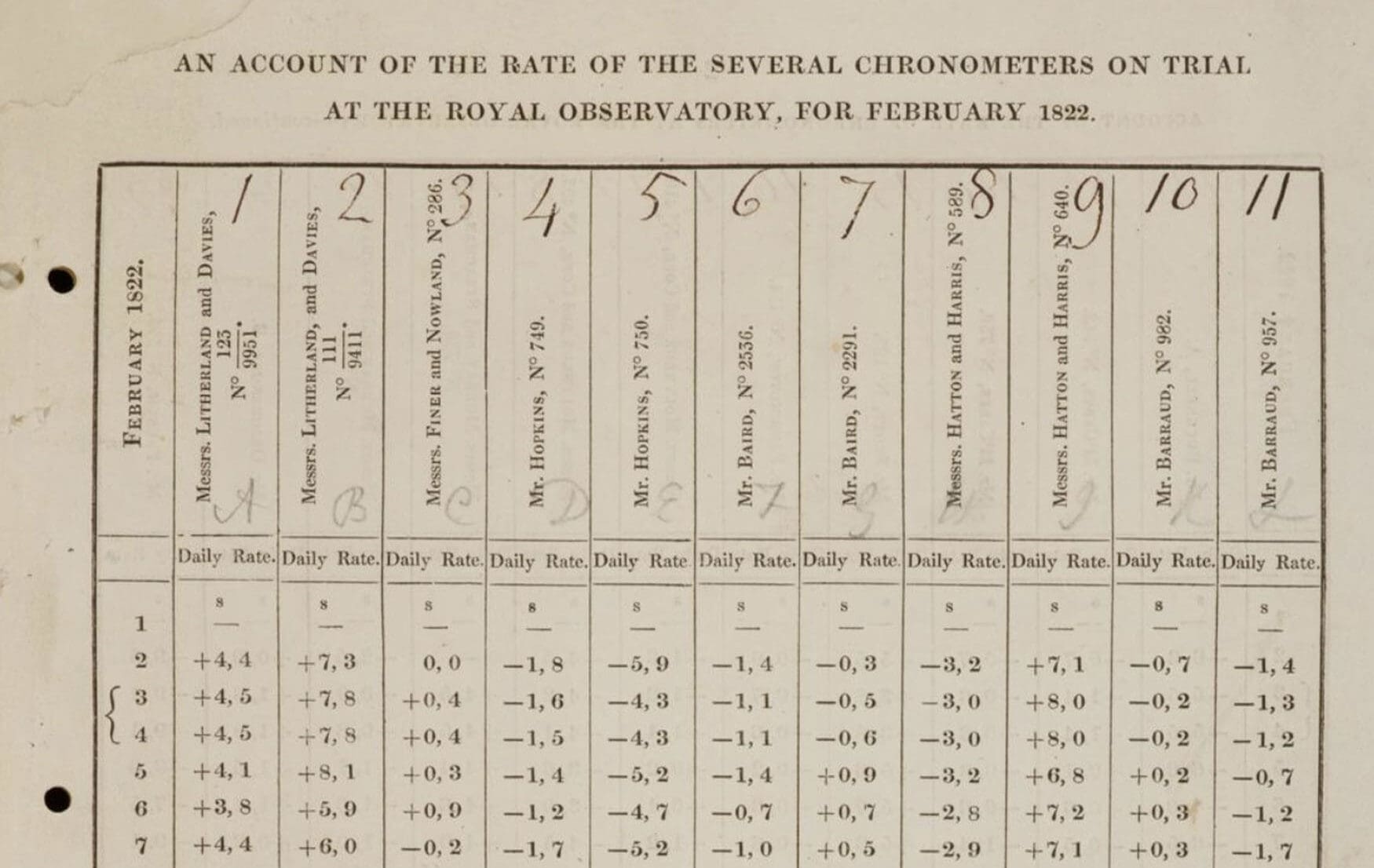

Even though the longitude problem had technically been solved, and several clockmakers were now capable of making marine chronometers, technology didn’t surge as quickly as it does today. They were prohibitively expensive even for the wealthy, and initially could cost up to a third of the cost of the ship itself. It took around four decades for manufacturing to catch up with demand, and the British Royal Navy could only start supplying its ships with chronometers regularly in the 1820s. Affordability was still a while away, but introducing some healthy competition was an idea from WJ Frodsham of Parkinson & Frodsham clockmakers to encourage development of high-accuracy chronometers. The Board of Longitude and the Admiralty were also supportive of this idea, as it allowed them to set the price, rather than the clockmakers.

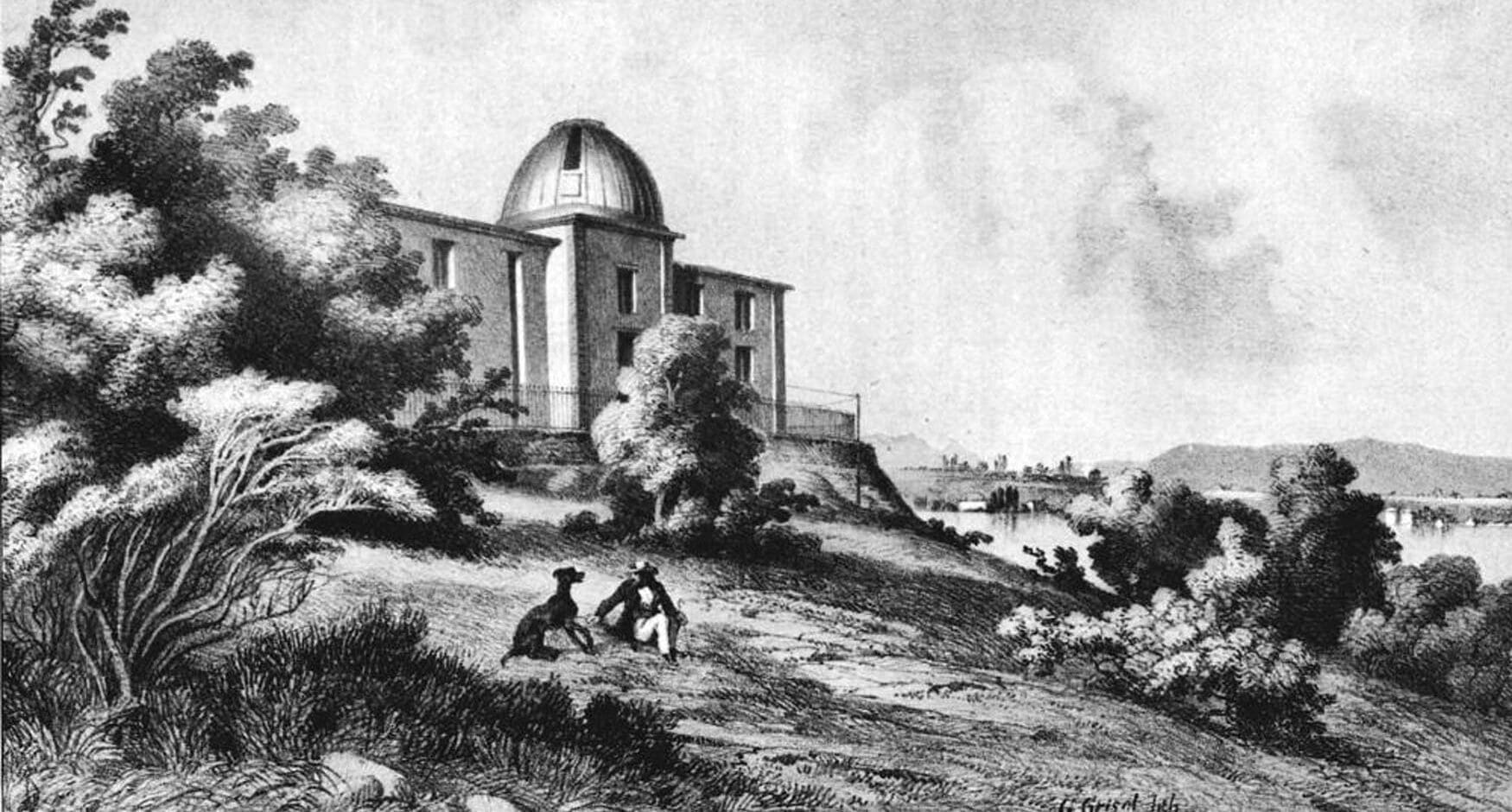

Given that time measurements were made from the movements of the stars by learned astronomers, it was only fitting that these annual chronometery trials would be held at Greenwich’s Royal Observatory. The first trial began in February of 1822, and 31 chronometers were entered. After a whole year, the best-performing chronometers were purchased by the Admiralty at £300 for first and £200 for second-placed watches. This system didn’t exactly work out however, as twelve years of trials didn’t seem to produce any meaningful developments in the slightest. In fact, some entrants submitted watches that they hadn’t even made themselves just for a shot at the prize money. Those trials were discontinued in 1836 and later reformatted, but England wasn’t the only country with a vested interest in chronometry.

The clear skies above mountains in Switzerland made for ideal observatory placement, and the Neuchâtel Observatory founded in 1854 was perhaps the most famous. Along with observatories in Geneva, Besançon in France, and the Kew Observatory in London, chronometer trials found a rhythm which actually did attract talent and innovation. Usual test periods of 45 days measured their performances across varying positions and temperatures, and satisfactory examples were awarded the Bulletin de Marches certification. It was an award which carried great prestige and marketing power, making for a much more compelling competition than a simple cash prize. No longer was the pool of chronometer-capable clockmakers limited to just Britain, and Swiss companies like Ulysse Nardin were catapulted to the forefront of reliable reputation.

Coming up to the turn of the 20th century, American production methods were showing the world what ruthless efficiency could be. Production lines cut down on labour, as did interchangeable components and industrial machines. Workers were not happy, but output and profits skyrocketed, and the price point dropped. Switzerland’s economy was booming after successfully adopting American business models, but the world of marine chronometers was still moving slower than its humbler pocket watch counterparts. The streamlining of production grew over decades, but didn’t explode until World War II. It should come as no surprise that the Americans achieved mass-production first, with Hamilton pumping out thousands of the Model 21 and 22 for the Allies in the 1940s.

After World War II, the nation which produced the most marine chronometers was actually the Soviet Union. They confiscated the technical drawings for Germany’s chronometers called the Einheitschronometer, and ended up making about 50,000 of them. The global need for them was beginning to reduce though, as peacetime meant there were fewer naval vessels operating. There was also the fact that most marine chronometers were built to incredibly high standards, and ships rarely needed to replace them once they had them. Demand continued to ebb, and observatory trials turned their eyes to the wristwatch which had been radically popularised in the last few decades.

The development of mechanical marine chronometers really hit a wall in 1967, when the global definition of one second changed from a fraction based on Earth’s rotation. Now based on the more reliable metric of a caesium atom’s radiation cycles, ships could also gain the benefit of quartz technology which was far cheaper and more reliable than even the best mechanical movements. In the mid-1980s, both the British Ministry of Defence and the US Navy got rid of their Hamilton mechanical chronometers which were only used sparingly as backups, as GPS navigation had been deemed reliable. The fizzling end of the marine chronometer’s heyday might seem sad to some, but the speed at which they came and went is truly a testament to how much they changed navigation. Without them, the progression to digital systems couldn’t have happened, and the romantic ideals of chronometry are still alive and well in high-end wristwatch movements today.