Zach’s visit to the IWC manufacture in Schaffhausen reveals the importance of ‘IWC-manufactured’

Zach BlassMore often than not, when we engage with watches it is typically in a retail shop, watch fair or watch meetup. But the exhibition caseback of any watch brand is a visit to their manufacture. Visiting a manufacture is truly a window into the brand, and not just in the behind-the-scenes sense of seeing the watches being made. Beyond getting an in-the-metal peek into processes, a manufacture visit is, in effect, a visit to the brand’s home and gives you a full picture of what any given manufacture is about. The majority of Swiss brands, typically lean Swiss-French and have carved a horological home in places like Le Locle or La Chaux-de-Fonds. IWC, however, is proudly Swiss-German, and is one of only two well-known manufactures to call Schaffhausen home (the other being H. Moser & Cie.).

Walking up to IWC’s latest home of manufacture, which opened its doors in 2018, you immediately get a sense of its expansive scale. I hesitate to say it feels like you are stepping up to a California mansion in the hills, but it certainly has a handsome quality. The reason I hesitate to give it a Hollywood association is due to the fact that glamour and flash is absolutely not what IWC is about – at least at their core. While some brands really lean into luxury, and make sure you know before leaving their doors the who’s who VIP list of famous clients and commissioners of their pieces, IWC really emphasised the people behind the brand and products they manufacture.

Sure, the lobby with its nine-metre high ceilings has an imposing grandeur. But, it was clear from the outset that nothing within the manufacture was meant to be lavish. It was about creating a home and hub where all of the machinery, those manning them, and other IWC employees continue to strive towards IWC’s consistent mission since its birth in 1868 of making superlative watches.

Adjacent to the entrance, on a wall immediately to the right, framed portraits of various leading figures within IWC are precisely adorned on the warm wood. And, from founder Florentine Ariosto Jones, to Günter Blümlein, and legendary watchmaker Kurt Klaus, it seemed to me the running theme was creating precise, practical and purposeful high-quality watches which did not self-promote or bend to hype. There, perhaps, was a strategic somberness that emphasised a winning cost-benefit for both the manufacture producing the watches and the consumers who purchased them. If the Swiss-French look to how to make watchmaking more complicated, IWC in their Swiss-German lane sought to show their know-how of complications but with a user-interface that kept things as simple as possible for the wearer. This is one of the many ways Kurt Klaus made his mark in watchmaking, with a perpetual calendar system that introduced an unparalleled ease of engaging with and setting the complication – yet was no less luxurious.

At present, IWC continues to emphasise watchmaking as a science, rather than an art form, with less romance and more pragmatism. This is not to say IWC is incapable of such pursuits (trust me they have produced highly artistic enamel-painted dials in the past). But walking through the manufacture it does not by any stretch feel like a museum (which they do have in a separate location that is well worth visiting). It feels like you have broken into a very high-tech lab, as there are no barriers between guests and the manufacturing processes. There is simply an honour system that you do not step beyond the grey border of the floor, at least not without permission.

That restriction is not so much about the preservation of state secrets, it is more that their expansive assembly lines are hard at work and, with precision and performance paramount, these processes are not to be interrupted – they are to be observed.

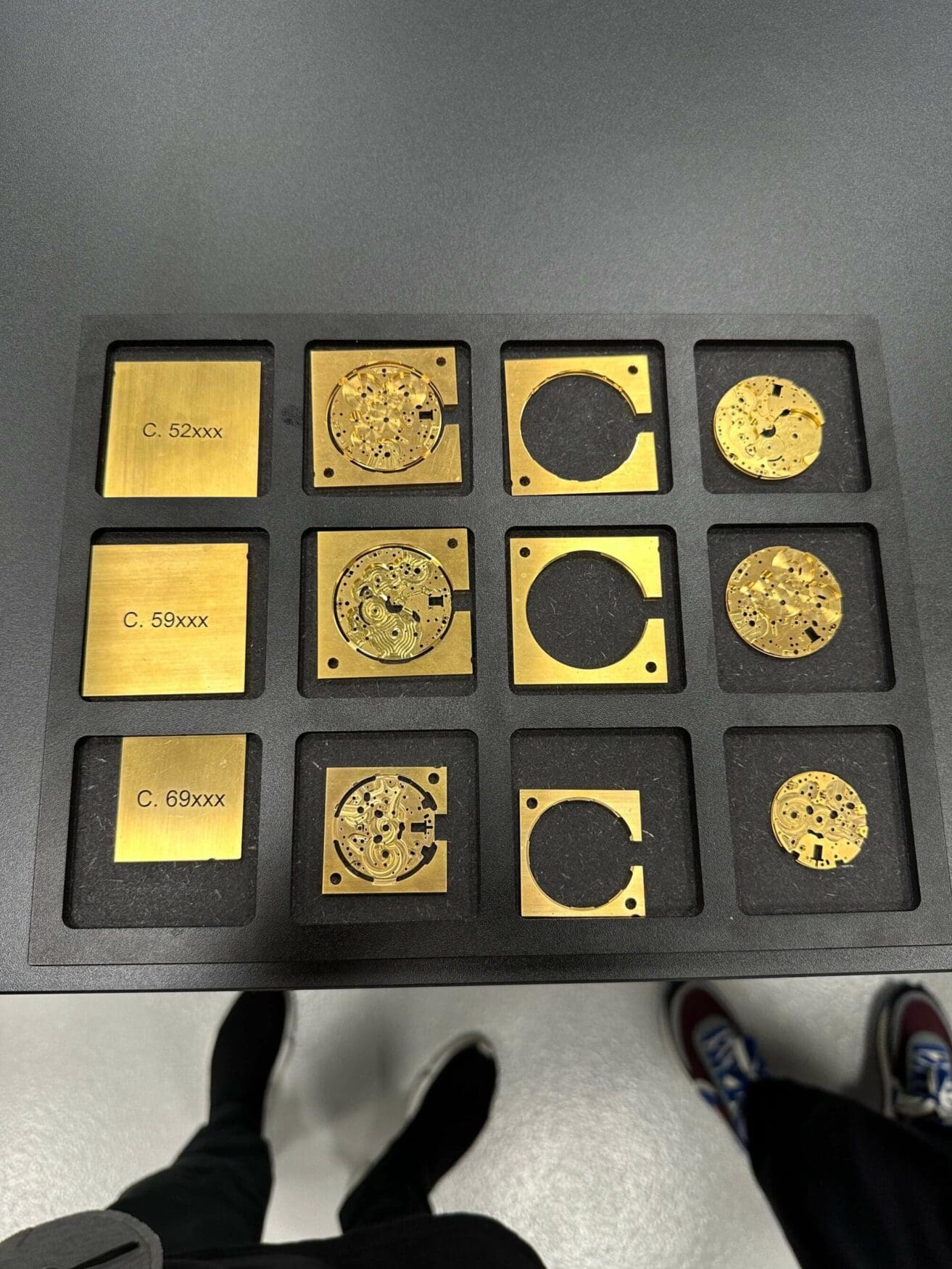

Within the manufacture, I was told approximately 2,000 components are manufactured within the confines of the building. In the watch world today, enthusiasts and collectors are very attracted to the notion that a watch brand manufactures things “in-house”. It is no secret that there are IWC calibres which are not original IWC architectures, and, appropriately IWC does not advertise these particular calibre lines as such. But, like in tennis, when you speak of the adage it is not the racket, it is more so the person holding it, the analogy applies. This is why IWC emphasises the notion of IWC-manufactured, and how they are able to control the quality and tolerances of the internals and externals of their watches at all times.

While the space is referred to as the movement assembly line, it is more human than you might expect. Sure, IWC is very industrious and there are certainly machines pressing teeny-tiny jewels into bridges, but nothing is without human intervention and assembly. Side note: people often forget that CNC machines are programmed by human beings, and that the output is only as good as the human being doing the programming. Very sciencey, but, in a manner of speaking, a modern art form nonetheless.

One memorable experience was seeing an expansive wall filled with rod after rod of various case materials. What was on display was by no means the entire stock of their materials, but the scale in-person was just insane.

These materials included raw rods of Ceratanium which is exclusive to the IWC manufacture. There are then stations nearby that display cases, in various materials, in their various stages of their manufacture – exhibiting the journey from rod form all the way to their final stage where they’re finally strapped to a wrist.

It was interesting to really get a chance to see and feel why watchmaking at this level will never truly eliminate the human hand, as machining can only take things so far. I was handed a machined case, and was instructed to carefully rub my fingers to get a sense of how sharp a machined case can feel. Then, after a watchmaker, in front of me no less, proceeded to perform his hand-guided finishing to the case, I was then able to feel just how more smooth the various facets can feel – the case still warm from the wheel turning on its surfaces (like a bun fresh out of the oven).

If you have arrived at the end of this story disappointed I did not dig deeper into calibres, components, and processes such as their CNC wire electric discharge machines that have insane tolerances within 0.001 millimetres, I apologise in advance. But this is all information that is by no means guarded and kept secret, in fact you can get some highly technical information about the IWC manufacture directly from the horse’s mouth right here (the opening of the manufacture), here (an inside look within various areas of the manufacture), and here (manufacture processes and production techniques).

Instead, what I aimed to offer is an understanding of how IWC is different philosophically, and how this philosophy sets both their engineers/artisans and their products apart from other manufactures. And, at their core as I said before, the vibes I received during my visit were at no point pretentious, boisterous or lavish. For me, in a world that emphasises “Swiss Made” and “in-house” perhaps to a fault, it was all about maximising and maintaining what it means to be “IWC-manufactured”. An understanding that in over a century of operation, it has always been about consistent execution, reliability, robustness, legibility, and clean design, while also never shying away from the next chapters of watchmaking. There is a proud tradition being continued within these walls, but each day is also spent looking to the future and modernising – whether revolutionising the experience of a perpetual calendar or innovating new materials such as Ceratanium.