Tudor vs Rolex is no longer such a fanciful comparison and a visit to the new manufacture shows why

Luke BenedictusAt Watches & Wonders this year, one night I accidentally got on the wrong bus from the Palexpo convention centre and found myself whizzing through the streets of Geneva in an unfamiliar neighbourhood. Aware of my plight, a kindly local on the next seat advised me where I should get off and we then struck up a conversation. This being Switzerland, it turned out the man had formerly run the marketing departments of two significant luxury watch brands and was now involved in a horological club that organised trips for collectors to experience the various manufacturers first-hand. When I mentioned that I’d just visited Tudor, the man smiled. “To be honest,” he said, “These days Tudor offers such great value I wonder why people still bother trying to get a Rolex.”

OK, I’m paraphrasing the man slightly here – I didn’t stick a voice-recorder under his nose on the bus – but you get the general sentiment. And it’s a point that, while contentious, is worth further exploration. Rolex is, of course, the most coveted watch brand in the world. It makes famously reliable watches of superlative quality. Yet given the current waiting lists for a Rolex and the significant disparity in price with Tudor, the man on the bus was making a fair argument. Why wait for a Rolex when you can buy a Tudor with relative ease and get a watch of sufficiently high quality that you might increasingly question paying so much more?

It’s not a sacrilegious comparison. This, after all, was what Hans Wilsdorf – the founder of Rolex and Tudor – was originally trying to achieve. Wilsdorf even articulated this vision explicitly. “For some years now, I have been considering the idea of making a watch that our agents could sell at a more modest price than our Rolex watches, and yet one that would attain the standard of dependability for which Rolex is famous,” he explained in 1952. “I decided to form a separate company, with the object of making and marketing this new watch. It is called the Tudor watch company.”

Today, Tudor is closer to achieving Wilsdorf’s vision than ever before. There’s no doubt the brand makes high-quality watches – they’ve had Master Chronometer pieces in their range ever since 2021. But what’s perhaps more impressive is that Tudor manage to make these watches at comparatively modest prices. My visit to their new manufacture in Le Locle offered some insights into how the brand manages to do this, with their entire operation designed around keeping costs down while delivering excellent value.

The Tudor Manufacture

Situated in Le Locle, a town on the north-western border of Switzerland, Tudor’s spanking new facility is the brand’s first independent production site. The fact that they’ve physically separated their watchmaking from Rolex feels like a statement in itself. Tudor has, of course, gained considerable momentum in recent years as an independent entity. But it’s now literally moved out of Rolex’s shadow.

At the beginning of this first-ever press tour, Tudor’s Head of Public Relations, Christophe Chevalier stood up to address the group. “What you will see here is the Tudor way of doing things,” he explained. “We want to optimise everything as much as possible. Our whole organisation is prepared and deployed so that we can make this happen. What we do here is bring the traditional, manual know-how of the watchmaker together with the absolute best in production management technology.”

Christophe’s emphasis on the process optimisation and production management was not accidental. The whole tour was designed to highlight how Tudor delivers high-quality watchmaking at an accessible price by ensuring maximum efficiency and harnessing the power of technology. The best part? It seems to involve lots of nifty robots.

State of the Art

As you’d expect, the manufacture is state-of the art. Sprawling over 5,500 square metres and four floors, the Tudor facility is connected to the Kenissi movement manufacture. Tudor founded Kenissi in 2016 and it now makes calibres for brands including Breitling, Chanel, Norqain, TAG Heuer and Fortis. To delineate the two entities from the outside, the Tudor section is bright red while the Kenissi section is a more subdued grey colour. Visually, the buildings looks like a modern-art gallery, but the aesthetics play second fiddle to their advanced functionality. The Tudor manufacture is purpose-built for sustainability with 442 solar panels on the roof and a special heating, ventilation, and air conditioning system that eliminates dust – a watchmaker’s biggest enemy – by renewing the air supply renewed up to five times every single hour.

High Performance

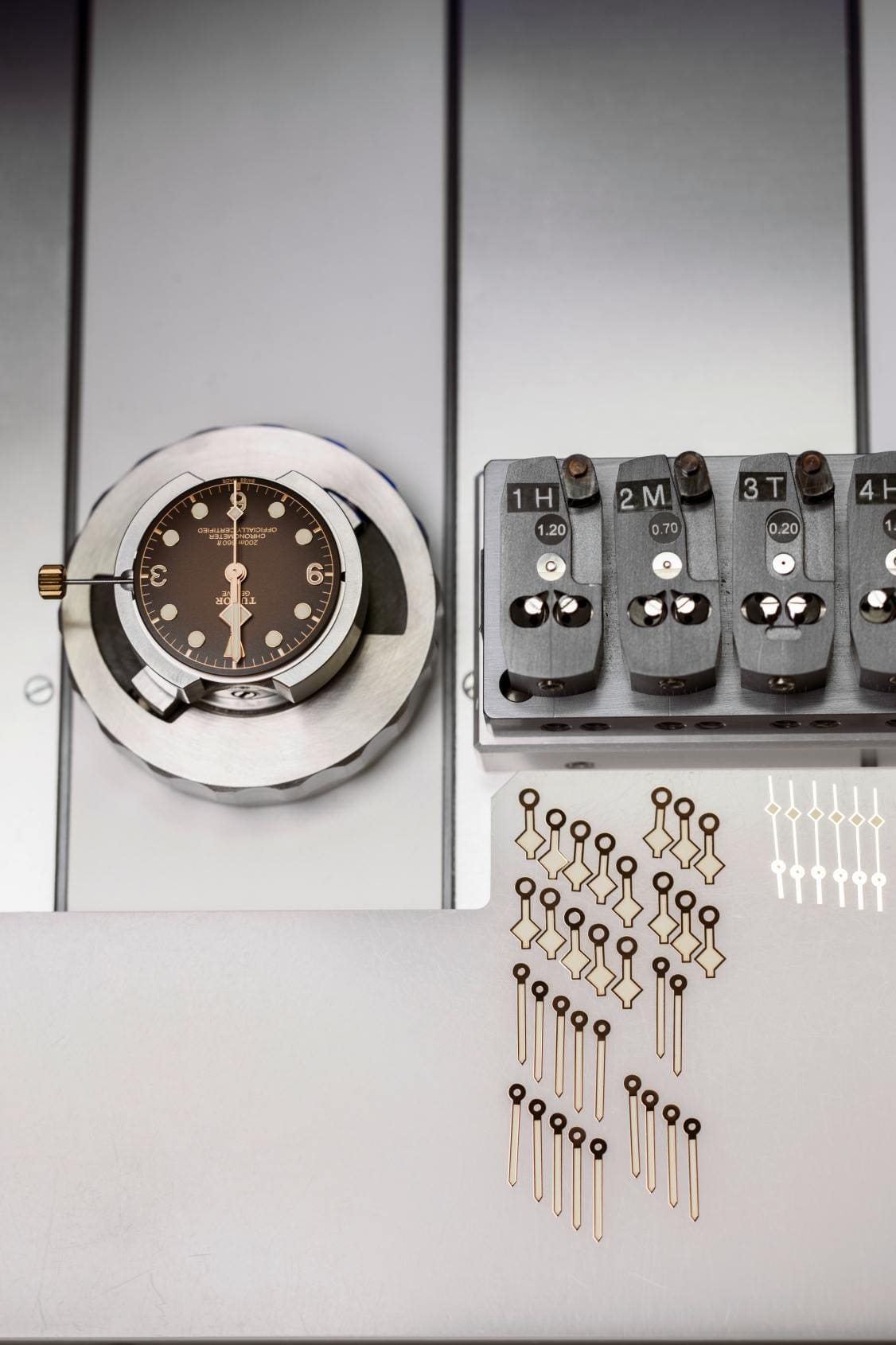

Tudor may be commonly viewed as Rolex’s little brother. But if you want to push the analogy, this younger sibling is determined to ensure that it’s taken just as seriously as a high-quality proposition. That much is clear when you see the integrated testing systems to help the watchmakers with the manual assembly of movements.

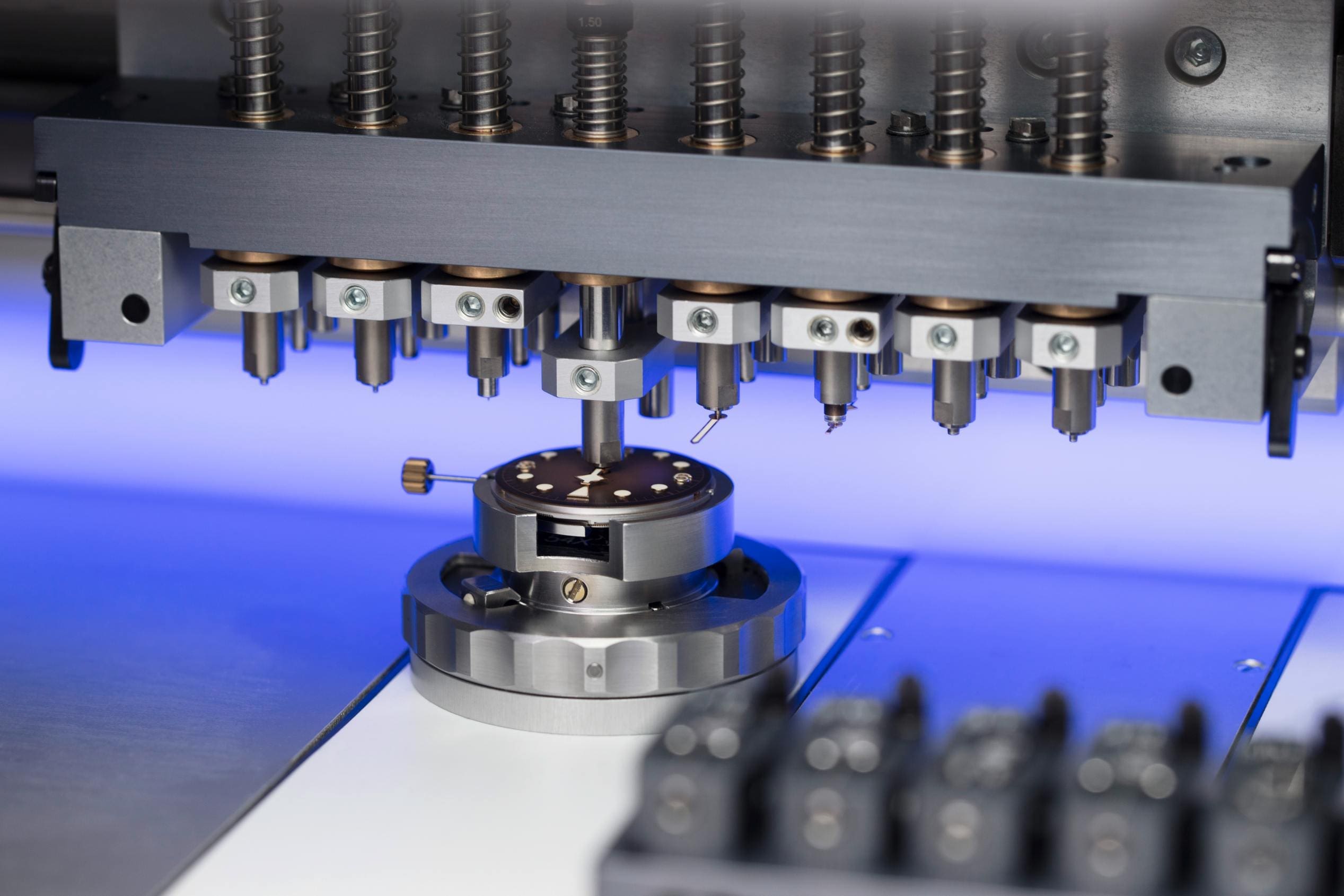

The testing floor runs 24/7 and is home to 46 tons of machinery that it use to ensure every watch meets two testing protocols. The first is METAS, the benchmark administered by Switzerland’s Federal Institute of Metrology for Master Chronometer certification that makes every watch pass eight punishing tests that include accuracy (-4/+6 seconds per day), autonomy (70 hour power reserve), water-resistance (200m) and anti-magnetism (15,000 gauss). Not content with the rigorous testing, the watches must also pass Tudor’s in-house measure called TPC (Tudor Performance Control). At one point, we see robots plucking watches from a vast array of trays to plug them into a machine where another robot tests their timekeeping accuracy at random.

In short, Tudor watches are held to formidably high standards. Once again, however, the reason this is so impressive is the bang for buck they deliver. Tudor’s all-ceramic Master Chronometer, for example, retails for $7140. Omega’s all-ceramic Seamaster 300 Master Chronometer is $13,300 – that’s almost double the price.

Automated stock

How Tudor manages to keep the costs down in this manner is again due to the emphasis on maximising efficiency. One of the best examples of this lies at the heart of the building where the brand conceals its cutting-edge solution for production management. This is Tudor’s automated stock system – an innovation the brand is both proud of but reluctant to display fully to visitors, keeping the action shielded behind reinforced concrete walls.

Essentially, the automated stock system is designed to ensure all the watch components are made available to every watchmaker for maximum convenience. When putting a watch together, the watchmaker can simply order the parts that are then quickly grouped together by robotic hands. The pieces are then whisked to the watchmaker via a fully automated building-wide network of watch-tray-sized elevators and tracks. The necessary components for any Tudor watch are therefore always available whenever they need them. It’s an example of what Christophe foreshadowed at the outset of the tour, putting humans at the centre of the watchmaking process while harnessing the power of technology.

Ever since 2012 and the release of the first Black Bay, Tudor has been steadily gaining industry respect. But a tour of the new manufacture suggests that this brand is only just getting started. While Tudor may never leapfrog its older sibling when it comes to prestige and recognition, the future for the brand is looking very bright indeed.